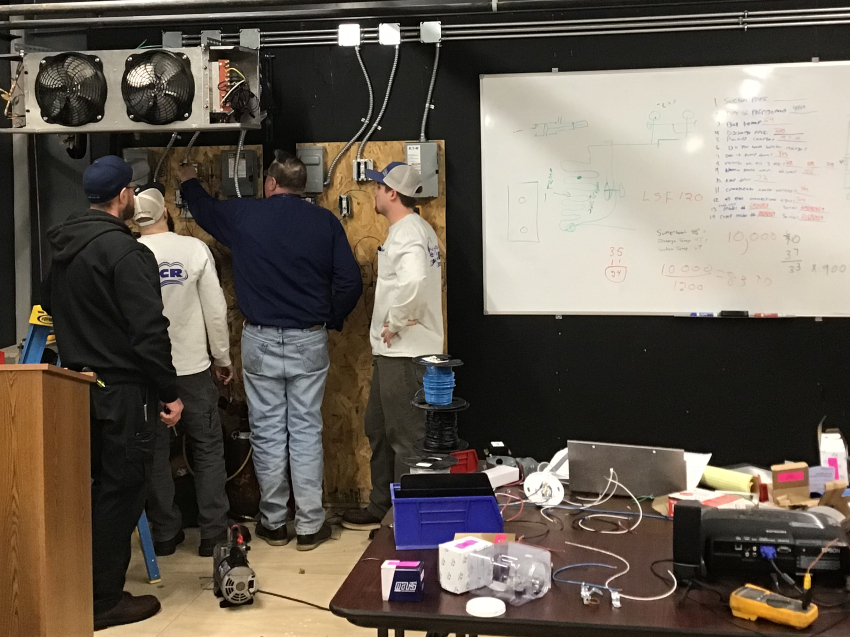

With new and advancing technology, it’s important for companies to keep employees up to date with information and processes. And recent funding has provided a helping hand. As grants allow for specialized industry training, local businesses like SCR develop competitive strategies.

THE SPECIFICS

St. Cloud State University recently earned $550,000 in training grants from the Minnesota Department of Employment and Economic Development. These grants were awarded in partnership with Grede Casting and SCR to subsidize specialized workforce training and equipment specific to each company’s needs.

Grede and SCR will work with local vocational colleges to develop and implement customized programs for current and incoming employees. Such practical training opportunities will help these companies remain competitive and improve workforce skills to adapt as industry requirements evolve.

With funding in place, the partnering businesses may expect novice employees to develop practical skills and experience to help further their careers and benefit the company. What’s more, these companies can anticipate a more robust workforce supported by industry-specific proficiencies.

In turn, the training schools — SCSU, St. Cloud Technical & Community College, Ridgewater College, and Hennepin Technical College — will establish programming and instruction for other businesses as well.

THE MJSP PROGRAM

Grant funding is provided under the Minnesota Job Skills Partnership (MJSP) Program, which offers training for present and future personnel. The program pairs participating businesses with accredited schools to build a foundation for enhanced instruction particular to the needs of the business or its customers.

Projects last from one to three years, with grants awarded up to $400,000. Each project requires at least one academic institution coupled with one business. Allocated funds may be used for training or to improve instructional resources of businesses currently in Minnesota or looking to relocate there.

SCR CONTINUES TO ADVANCE

SCR continues to advance and evolve to meet the ever-changing needs of its clients. As these grants allow for specialized industry training, SCR will use this opportunity to further its comprehensive approach to customer service and satisfaction. Embracing growth and new technology training will help this family-owned and operated business maintain its standing as the Midwest leader in commercial refrigeration, HVAC/R, building automation, and food service design, installation, and maintenance. To learn more about SCR, its capabilities, or its grant-funded training agenda, contact us or visit our website.