Organizations that construct or renovate spaces for themselves or for client use often rely on others to bring their vision to life. SCR, Inc. provides specialized efforts to help analyze and complete the job at hand. Jerry Theisen, Controls Group Manager for SCR, recently examined a challenging project. By conforming building automation for exact needs, SCR confirmed and enhanced its broad range of capabilities.

GETTING TO WORK

The Dayton at Gaviidae YMCA project required a complete remodel of an existing building. To handle the building automation, SCR was an obvious choice.

“Since we’re the YMCA’s primary provider for building management in the metro area, we were brought in to do this one,” Theisen said.

That includes virtually any automated system within the structure: lighting, HVAC, pools, saunas. “We do everything,” Theisen added.

INTEGRATION PROCESS

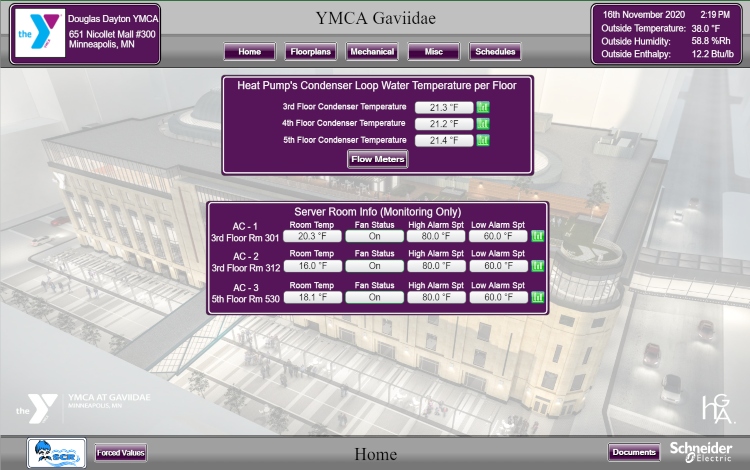

The existing structure was equipped with more than 50 heat pumps to provide zone control for different areas. And that’s important for a place like the YMCA. The temperature needs vary greatly among spaces for offices, dance studios, pools, and weight rooms, Theisen noted.

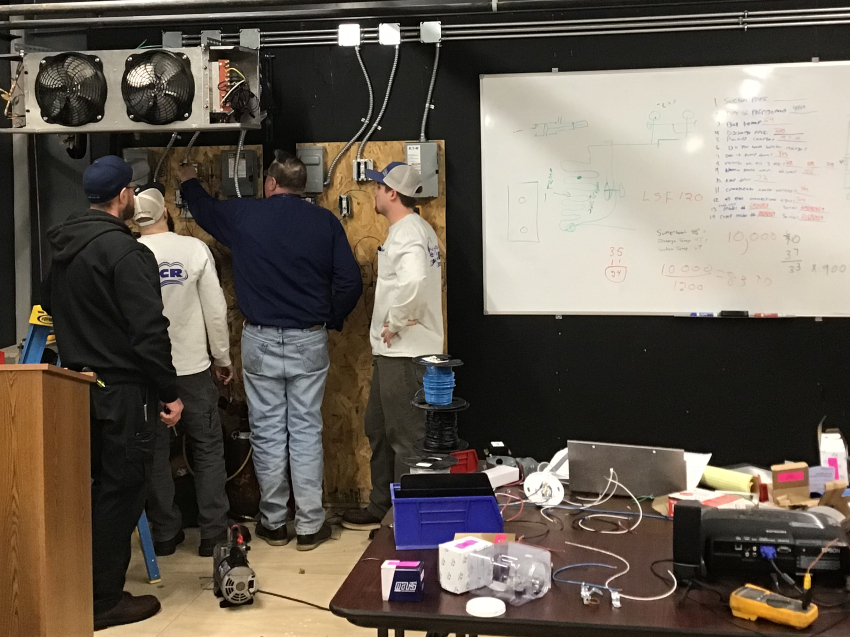

SCR studied the building and the project beforehand and was able to combine some of the older equipment into the new system. As a Schneider Electric partner, SCR utilized the EcoStruxure™ Building Operation platform to provide all the needed controls and optimization.

“This was an engineered project, so we took their design and brought in the controls to make it perform the way it was designed,” Theisen said.

Integrating old and new systems wasn’t the only challenge.

Because this is a historic building, Theisen said the year-long project involved uncovering some surprises along the way. Whether that was working through thick, concrete walls or automating controls for an upper-level swimming pool, SCR was ready.

“We did it,” Theisen said, “and it worked.”

EXPERIENCE AND EFFICIENCY

With a project like this, Theisen noted that having a broad scope of capabilities goes a long way. Because of SCR’s previous work and high level of experience, the team was ready to handle any curve balls on this unique project. Accordingly, the work completed on this YMCA project provides even more experience toward future endeavors.

“All of it kind of goes together,” Theisen said.

Ultimately, SCR brought together dissimilar systems in a common front end to provide the specific sub-climates and controls for the Dayton at Gaviidae YMCA, all while accommodating schedules with other trades.

“This was a fun project,” Theisen added, “and it turned out very nice.”

SCR is no stranger to a challenge. By conforming building automation for exact needs, the team capitalized on its experience to provide efficiency and a wide range of comfort. To learn more about how SCR’s state-of-the-art controls can provide the building automation you need, contact us today.